Case 075: Breaking the pump

body.

On October 12, 2001, at 5h20m, an oil tank operator

located next to a dock the bank of the river Seine in the commune of

Hauts-de-Seine (nearby Paris), France, was alerted by a driver who heard a strange

noise in the pump station No. 1. By checking this alert, discovered a furnace

fuel oil spill (Furnace Fuel Oil - FFO) that flooded the pit retention of pump

station with about 80 cm of FFO.

The leak occurred in a tank farm consisting of 23 tanks, each with a

nominal capacity of between 537 m³ and 19 193 m³, for a total nominal capacity

of approximately 107,000 cubic meters.

CAUSES

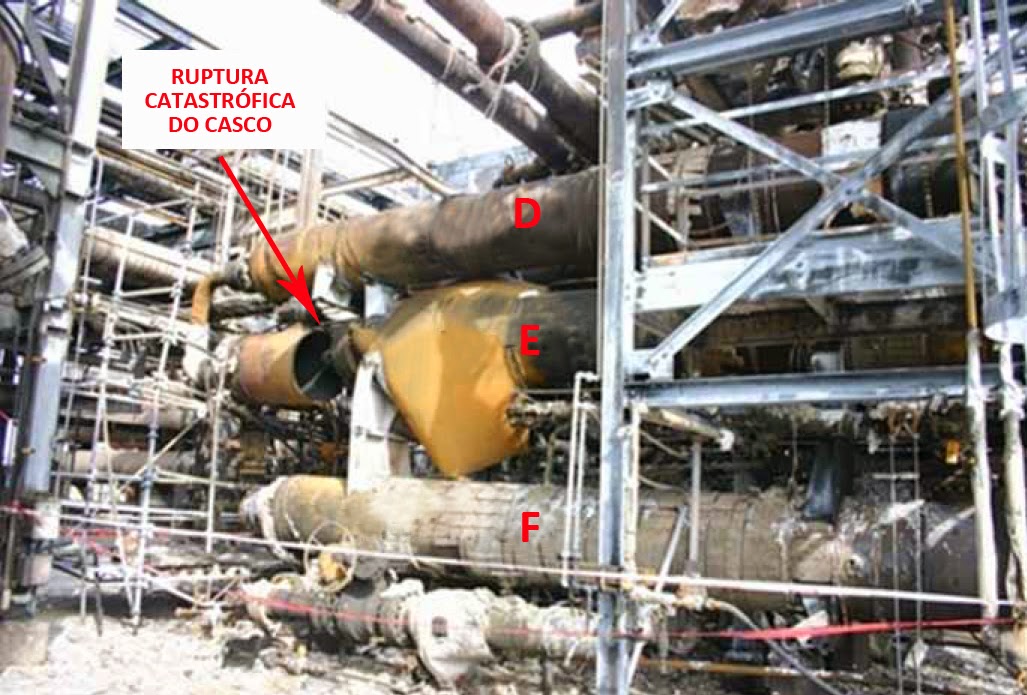

The leak occurred in the No. 01 pump station where one of the bombs had

your body (housing) broken due to the accumulation of excessive stresses

associated:

·

Incorrect

support lines and accessories lines (suction and discharge);

·

Lines

incorrectly connected to the pump.

The phenomenon was exacerbated by the nature of the pump (made of cast

iron) which did not support the stresses caused by poor installation of the

pump in place and the resulting mechanical vibration.

Furthermore, leakage of the product is possible as the result of various

disorders:

·

A liquid

hydrocarbon detector was set at 2 meters pump in question, but were dead at the

time of the incident;

·

FFO was

intercepted by a "trap" the gravity equipped with a plug (floaters)

that prevented the spill reached the Seine, but as the closing was not

immediate, several hundred liters of FFO leaked to the Seine;

·

The pump in

question was a back-up pump that was not in operation at the time of the

incident, however, an error, which was subsequently identified as bad

operational management, the valves were kept open permanently.

AFTERMATH

About 500 liters of FFO was improperly dumped in the Seine a distance of

3 km from the spill source point (iridescence was found along this stretch).

The loss calculated by official agencies was about € 200,000 (euros) can

be specified as follows:

·

Damage to property: € 112,000;

·

Environmental decontamination /

cleaning costs: € 23,000;

·

Operating loss: € 61,000.

LESSONS LEARNED

·

Insertion of

this type of scenario studies and risk assessment;

·

Keep closed

suction manual valves and discharge the back-up pump;

·

Further

evaluate pumps and pipes to draw up action plan based on the elimination of

tensions and check if the material used is suitable for the job. The plan

also allows the replacement of pumps that point similar problems;

·

Keep

hydrocarbon detectors in perfect condition so there is the rapid closing of

valves during a detection signal, either liquid or gas.

PROPOSED STUDIES

·

System study

fast closing of these valves for the detection of the leak;

·

Verification

of the correct positioning of the hydrocarbon detection device located at the

outlet of the separator. The device must be located in the discharge line

downstream of the shut-off valve to prevent any discharge into the

Seine. In case of detection, reaction and valve closing time must be taken

into account,

·

A study on

the installation of a floating fixed permanent barrier in the Seine release

point. This possibility of having a boom operating permanently presents

some problems to the dock;

·

Study on the

closing of all valves of pump stations when the unit is out of operation.

Breaking= quebrando

Pump= bomba

Body= corpo

Operator= operador

Tank= tanque

Oil= oleo

Alerted= alerta

Checking= verificar

Furnace= fornalha

Flooded= inunda

Pit= poço

Retention= reter

Pump=

bomba

station = estação

Your health and safety: A guide for workers also

provides further details of your rights and responsibilities.

Your health and safety: A guide for workers also

provides further details of your rights and responsibilities.

.jpg)

.jpg)